Einblicke in die Anwendung

CareGlance

About CareGlance:

CareGlance s.r.l. ist ein Technologie-Startup aus Italien, das seit 2019 photonische Geräte für die Echtzeitüberwachung von industriellen Anwendungen entwickelt. Das Unternehmen hat es sich zur Aufgabe gemacht, die Optische Kohärenztomographie (OCT) durch MHz – Swept Sources und optische Integration in eine tragbare Echtzeittechnik zu verwandeln. Dabei konzentrieren sie sich auf Laserschweißen, additive Fertigung, Qualitätsüberwachung, Automobil- und Luftfahrt.

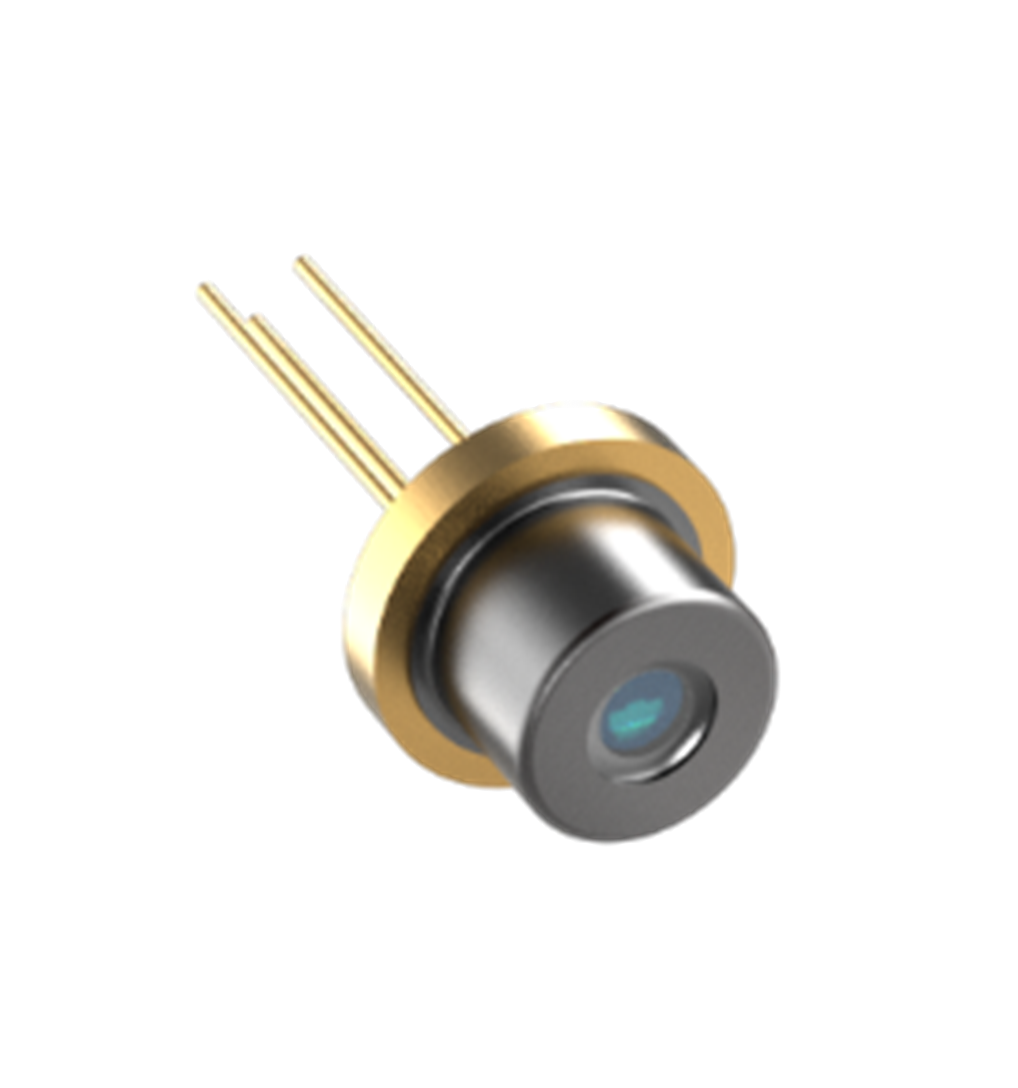

Produkt: RWE 810 nm

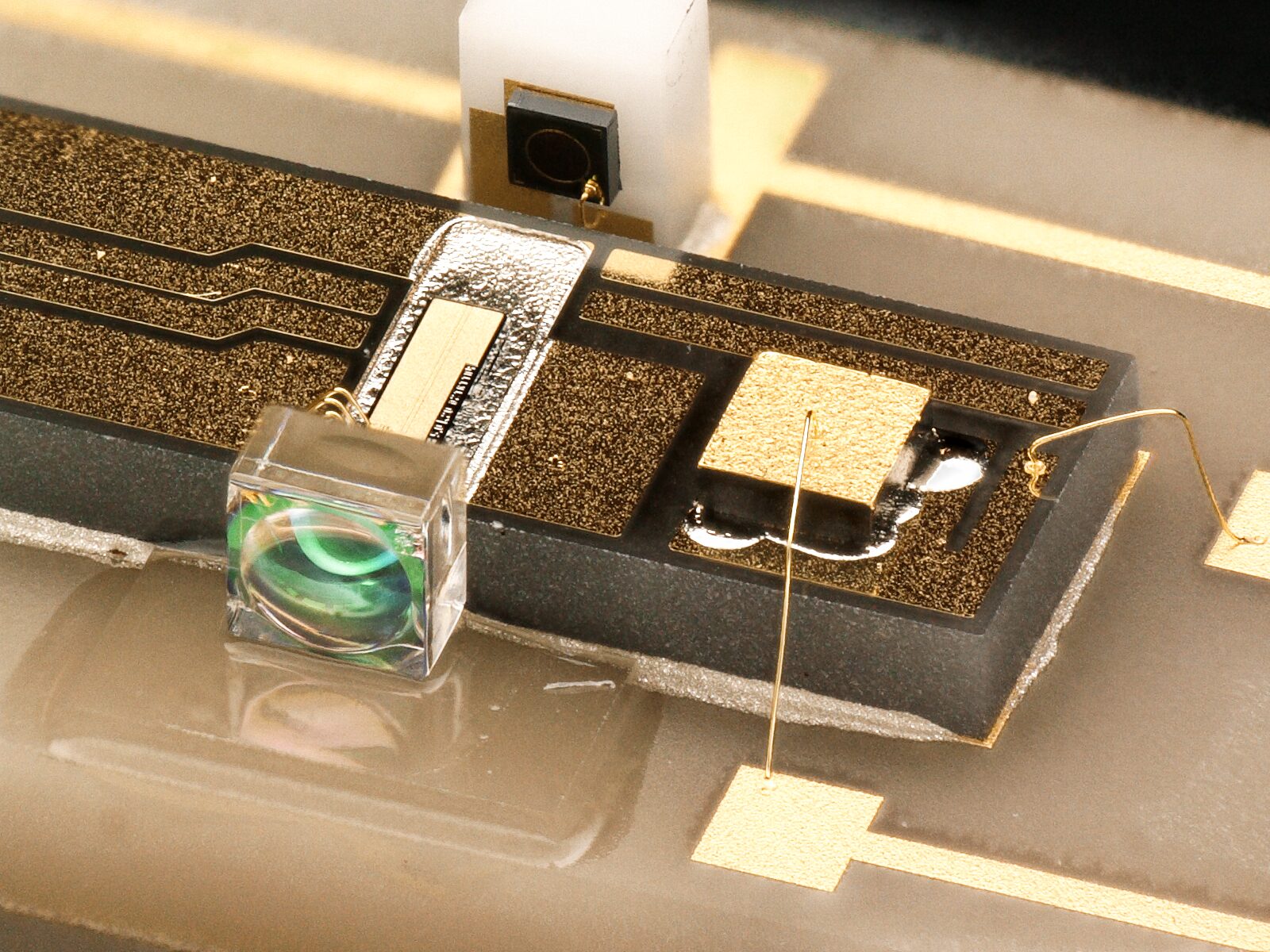

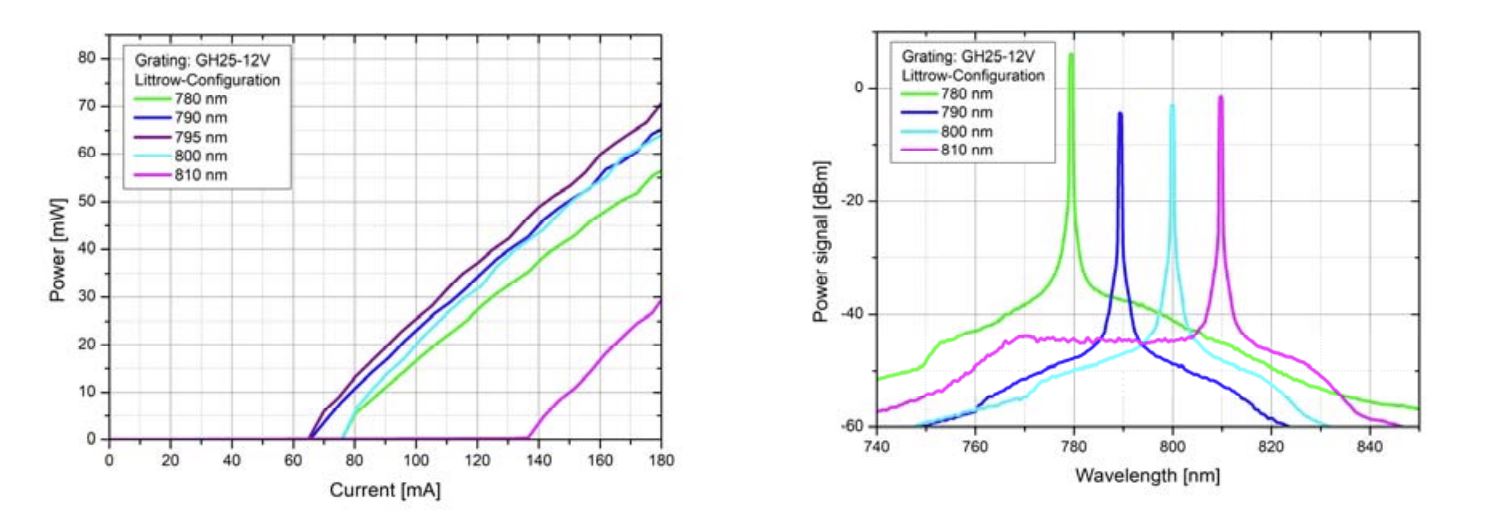

CareGlance is using the “RWE 810 nm” laser diode from TOPTICA EAGLEYARD. These RWE series gain chips are Fabry-Perot laser diodes featuring an excellent ARcoated output facet. Designed for operation in external cavity laser (ECDL) setups, such as Littman or Littrow configurations, these gain chips offer narrow single-frequency operation with a linewidth of less than 100 kHz when external feedback is applied. They also provide superior tuning capabilities across their entire gain range and high output power. EAGLEYARD offers these laser diodes typically packaged in a standard industrial TO-can (as shown in picture). Because of the innovative approach by CareGlance’s technology, a customized carrier for the laser diode was developed to enable higher integration.

Wavelength

Power

Laser Type

Operation Mode

810 nm

70 mW

AR coated

CW

In welchem Produkt verwendet CareGlance die Laserdiode von EAGLEYARD? Für welche Anwendung wird Ihr Produkt eingesetzt?

CareGlance:

In its swept source based optical coherent tomography system, developed for real-time monitoring of industrial processes. In particular, the semiconductor gain chip is used as active medium of our external cavity tunable source.

Können Sie uns einen Einblick geben, wie Ihr Produkt funktioniert und welche Rolle der Laser von EAGLEYARD spielt?

CareGlance:

CareGlance product is an Optical Coherent Tomography (OCT) system whose performance is enabled by a fast tunable swept source, that exploits a non-mechanical, electro-optic effect. The source is based on EAGLEYARD’s gain chip which is used as the semiconductor active medium of an external cavity laser structure. This system is especially designed to perform real-time monitoring (using a wavelength around 800 nm) of industrial processes: above all, the ones based on high power lasers, such as laser welding, laser cutting, additive manufacturing. This thanks to the “collaboration” between the laser source and a patented non-linear image reconstruction algorithm able to provide great accuracy even in highly noisy environment. All the newly developed features are IP protected and enable multi MHz A-scan frequencies, accuracy of few tens of microns, high reliability, and competitive price, in an underpopulated competitor landscape.

Wenn Sie eine andere Laserdiode verwendet haben, bevor Sie die von EAGLEYARD in Ihrem Produkt eingesetzt haben, was hat Sie dazu bewogen, zu wechseln? Was ist der Vorteil der ausgewählten EAGLEYARD-Laserdiode im Vergleich zu Alternativen/vorherigen Lösungen?

CareGlance:

The main motivation is related to the overall superior performance of the laser diode as far as concerning CareGlance’s application. EAGLEYARD’s product provides an optical beam with very low ellipticity and divergence: these features are mandatory to get an optimal laser performance and fiber recoupling to enter the interferometric section of the OCT. It’s easier to collimate such a beam inside the cavity with reduced astigmatism and ellipticity, both to avoid losses and favor coupling of the output to a fiber system.

Können Sie uns Einblicke in den Entscheidungsfindungsprozess für die Laserdiode von EAGLEYARD geben?

CareGlance:

The process was simply led by comparative analysis of the performance datasheets of some competitors’ products, together with experimental tests on few sample units to confirm datasheet indications and internal simulation about the chip behavior in CareGlance laser.

Wie haben Sie die Zusammenarbeit mit EAGLEYARD erlebt, von der ersten Anfrage bis zum Einbau des gesamten Auftrags in Ihr Produkt?

CareGlance:

In 2024 there has been a highly interactive collaboration with fast response from EAGLEYARD, both concerning extra tests to be performed on the diodes and customizations (i.e. soldering a thermistor on top of the gain chip carrier).

Wie zufrieden sind Sie mit EAGLEYARD insgesamt?

CareGlance:

CareGlance is pretty satisfied with EAGLEYARD’s collaboration in this prototyping phase and aims at strengthening the collaboration in order to set EAGLEYARD as a stable industrial partner for its future product lines. There could be room for customized development to get chips with golden performances, for example in amplified spontaneous emission power.

Wir danken CareGlance und Maria Chiara Ubaldi (CEO) für diese großartigen Einblicke!

You can download this application insight case.

KONTAKTIEREN SIE UNS

Bei Fragen und individuellen Anforderungen stehen wir Ihnen selbstverständlich zur Verfügung. Bitte kontaktieren Sie uns jederzeit. Wir sind hier, um Ihre Vision zu unterstützen!

info@toptica-eagleyard.com